ring die pabrik pelet kayu vertikal untuk pelet biomassa

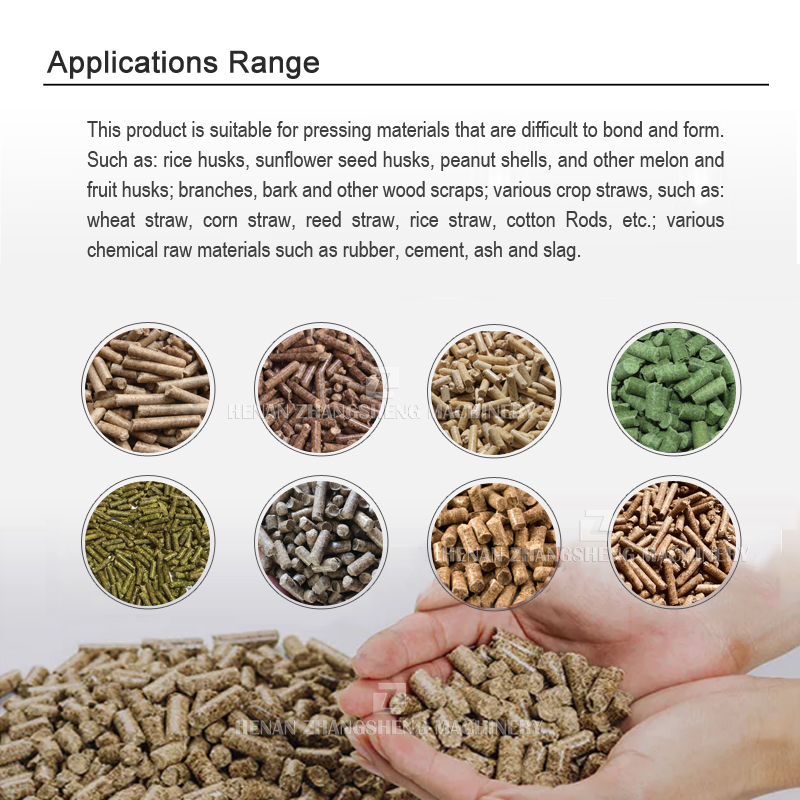

Biomassapabrik pelet kayuadalah jenis peralatan pelet baru.Bahan mentah dihancurkan dan diekstrusi menjadi pelet bahan bakar padat berbentuk batang kecil untuk dibakar.Dapat digunakan untuk mengolah jerami tanaman, jerami gandum jagung, jerami kacang, kayu tung, kayu cedar, kayu poplar, kayu buah, sekam padi, bibit padi, padang rumput, jerami, kulit kacang tanah, tongkol jagung, batang kapas, serpihan bambu, serbuk gergaji, sekam kamelia, cangkang biji kapas, sisa jamur yang dapat dimakan dan kotoran sapi serta bahan baku lainnya.

1. Pengumpanan vertikal, bahan dimasukkan secara jatuh bebas, dan mudah menghilangkan panas tanpa melengkung;.

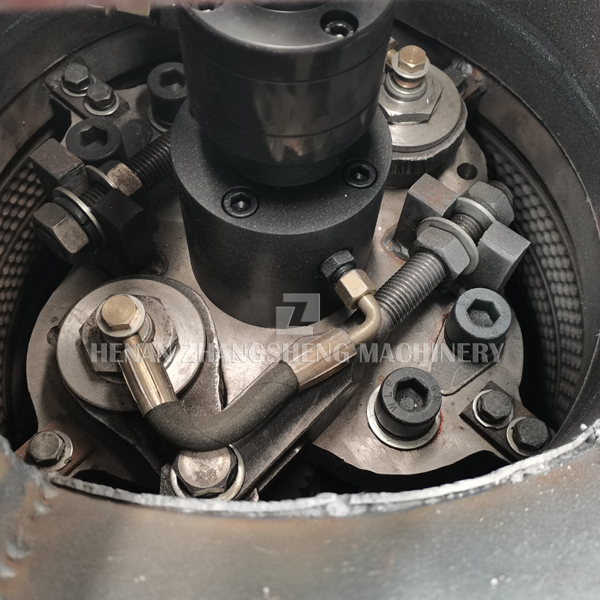

2. Rol tekanan berputar, material disentrifugasi, distribusinya seragam, dan laju pembentukannya tinggi.

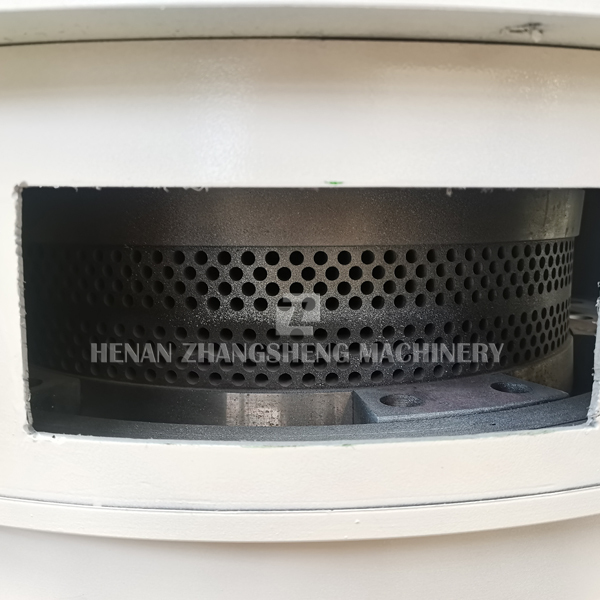

3. Cetakan diperbaiki, peralatan berjalan lebih stabil, dan lapisan atas dan bawah dibagi menjadi dua jenis spesifikasi rasio kompresi.

4. Bagian transmisi dan bagian pengepres mengadopsi dua set sistem pelumasan independen, yang aman dan stabil untuk pengoperasian jangka panjang.

5. Dilengkapi dengan penghilang debu berpendingin udara, pengoperasian jangka panjang, produksi efisien, hemat energi, dan perlindungan lingkungan.

| Model | LGX700A | LGX600A | LGX600 | LGX560 | LGX450 | |

| Kekuatan (kw) | Motor utama | 160 | 132 | 110 | 90 | 55 |

| Menarik Bahan | 2.2 | 1.5 | Penggerak spindel | |||

| Pompa minyak listrik | 0,37+0,65 | 0,37 | ||||

| Kecepatan (r/mnt) | 1450 | |||||

| Tegangan (v) | 380V, AC 3-P | |||||

| Ukuran pelet (mm) | 4-12 | |||||

| Suhu (℃) | 40-80 | |||||

| Kelembaban bahan baku (%) | 15-25 | |||||

| Bobot mati (t) | 8 | 7 | 6.5 | 5.6 | 2.9 | |

| Dimensi (m) | 24.6*14*20 | 22*12*17.5 | 31*13*21 | 23*12.5*20 | 21.6*10*18.5 | |

| Cincin mati Diameter bagian dalam (mm) | 700 | 600 | 600 | 560 | 450 | |

| Kapasitas produksi (t/jam) | 2.5-3 | 2-2.5 | 1.8-2 | 1.2-1.5 | 0,8-1 | |

1.Apakah Anda pabrik atau perusahaan dagang?

Kami memiliki pabrik kami sendiri.kami memiliki lebih dari 15 tahun pengalaman dalam pembuatan lini pelet."Pasarkan produk kita sendiri" mengurangi biaya hubungan perantara.OEM tersedia sesuai dengan bahan baku dan keluaran Anda.

2. Bahan baku apa yang bisa dibuat menjadi pelet biomassa?Jika ada persyaratan?

Bahan baku dapat berupa sisa kayu, batang kayu, dahan pohon, jerami, tangkai, bambu, dll termasuk serat.

Namun bahan untuk langsung membuat wood pellet adalah serbuk gergaji dengan diameter tidak lebih dari 8mm dan kadar air 12%-20%.jadi jika bahan anda bukan serbuk gergaji dan kadar air lebih dari 20% maka diperlukan mesin lain seperti penghancur kayu, pabrik palu kayu dan pengering dll

3.Jangka waktu pembayaran apa yang Anda terima?

Kami mendukung berbagai metode pembayaran, kami dapat menerima 20%-30% sebagai deposit.Pelanggan membayar sisanya setelah akhir produksi dan inspeksi.Kami memiliki lebih dari 1000 meter persegi bengkel stok spot.Dibutuhkan 5-10 hari untuk pengiriman peralatan siap pakai, dan 20-30 hari untuk peralatan yang disesuaikan.Kami akan melakukan yang terbaik untuk mengirimkannya sesegera mungkin.

4. Dimana pasar produknya dan dimana keunggulan pasarnya?

Pasar kami mencakup seluruh negara Timur Tengah dan Eropa dan Amerika, dan mengekspor ke lebih dari 34 negara.Pada tahun 2019, penjualan domestik melebihi RMB 23 juta.Nilai ekspornya mencapai 12 juta dollar AS.Dan sertifikat TUV-CE yang sempurna serta layanan pra-penjualan dan purna jual yang andal adalah hal-hal yang telah kami kerjakan dengan keras.